BEPT MBBR STP

MBBR advanced with BEPT sewage treatment plant.

Sewage Treatment Plant from “Watsoft Solutions”, Its state of art technology which uses unique proprietary SEED BIO-CULTURE UNIT which generates decomposing bacteria according to the organic load of the sewage input.

This BEPT process consists of continuous bacterial replenishment using SEED BIO - CULTURE UNIT along with biological coagulation, flocculation and settling which brings down the BOD and COD of the sewage.

WHY MBBR advanced with BEPT?

Advantages of MBBR advanced with BEPT Technology

- Requires Less Civil tanks as compared to conventional MBBR.

- Requires 35% Less Space as compared to conventional MBBR.

- 50% Less operating cost as compared to conventional MBBR.

- Small Submerged Aerators So Less Noise issues

- 100% Biological and No chemical used.

- Does not require skilled operator.

PROCESS AND FLOW CHART

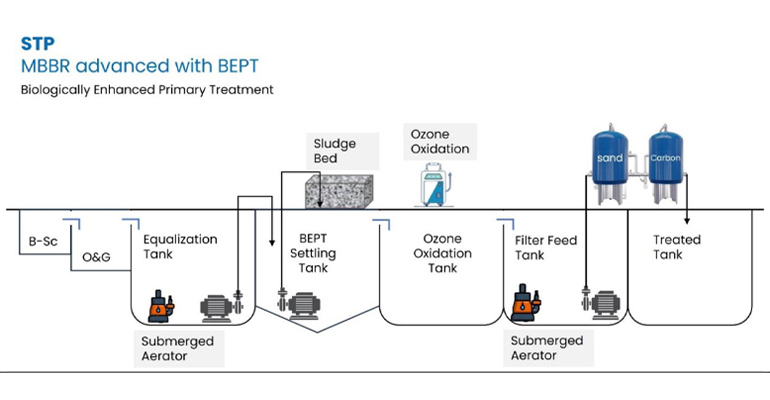

Flow process of Sewage treatment

Pretreatment : Pretreatment will consist of Bar Screening, Oil & Grease removal. Bar screen is provided to trap the large sized particle, plastic bags, debris etc. and oil and grease tank will be provided to separate the oil and grease from the sewage. From this tank the sewage will be transferred to equalization tank.

Equalization Tank cum Aeration Tank : This is raw sewage collection and equalization tank. The sewage flow will be equalized in this tank. This will act as the buffer tank for the shock incoming flow. Submerged aerator is used in this tank for aeration. Further sewage will be pumped in the next BEPT process tank.

Biological Enhanced Primary Treatment Tank : This BEPT process consists of continuous bacterial replenishment with seed bio culture unit where the biological coagulation, flocculation and settling takes place which brings down the BOD and COD of the sewage. The over flow of this tank is transferred to advance ozone ozonation tank.

Ozone oxidation Tank : The water is continuously circulated through the ozone oxidation system for increase of dissolved oxygen in the sewage water as well as disinfection purpose. This will reduce the harmful bacteria, algae, viruses, Molds (fungi) and other microorganisms which multiply and grow. This water is further transferred to filter feed tank.

Filter Feed Tank Cum Aeration Tank : The sewage water from FFT is further pumped for tertiary treatment. Tertiary Treatment Pressure Sand Filter (PSF) consists essentially of a pressure vessel. It is externally fitted with necessary pipe work, valves, and pressure gauges. The bed consists of sand, pebble gravel etc. It is required to remove suspended solids and turbidity from clarified water. Activated Carbon Filter (ACF) is used to knock off VOC (Volatile Organic Compounds) normally associated in almost all sewage treatment plant. ACF also helps in giving polished look to treated water.

Sludge Removal and Sludge Drying Process : The sludge which is removed from the BEPT tank is transferred to sludge drying bed or decanter system or filter press for the appropriate disposal of sludge with the help of specially designed decomposing bacteria.

Our other products and solutions

- Organic Waste Composter for Wet Garbage

- Rapido Composter Machines

- Roto Composter Machines

- Energia Bio-Digesters

- Water Conditioners for Hard Water

- Anti-Smog Guns for Dust Settling

- GFRP Rebars

- Soil Conditioner for Agriculture Soil